Luxury Rigid Boxes Are Available Here In New Styles

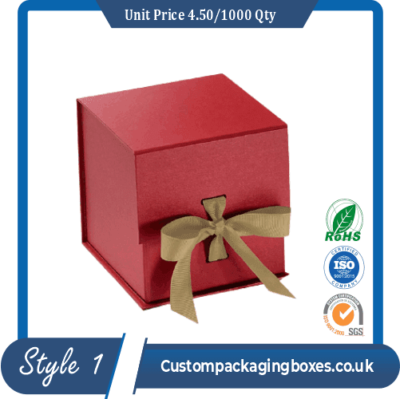

Styles 1

(Luxury Rigid Box With Logo)

A luxury rigid box with a logo is a high-quality packaging solution that is designed to provide a premium look and feel to the product it holds. The box is made from sturdy materials such as cardboard, which are reinforced to make the box more durable and long-lasting.

The logo is typically printed on the exterior of the box using high-quality printing techniques, such as foil stamping or embossing, to give the box a sophisticated and elegant look. This type of packaging is often used for luxury products, such as high-end cosmetics, jewellery, and electronics, to create a premium presentation for the product.

Luxury rigid boxes with logos are available in a wide range of sizes, shapes, and colours, and can be customized to meet the specific needs of a brand or product. They can also be embellished with additional features, such as magnetic closures, ribbon ties, or foam inserts, to provide additional protection and enhance the overall presentation of the product. Luxury rigid box with a logo is an excellent packaging solution for brands looking to create a premium look and feel for their products and stand out in a crowded marketplace.

Styles 2

(Luxury Rigid Box Unprinted)

A luxury rigid box is a high-quality packaging solution that is made from sturdy materials, such as cardboard and is designed to provide a premium look and feel to the product it holds. However, unlike a luxury rigid box with a logo, a luxury rigid box unprinted is a plain box that has no printed design or branding on its exterior. This type of packaging is often used for products that do not require branding on their packaging or for brands that prefer a minimalist look. Luxury rigid boxes unprinted can be used for a wide range of products, including cosmetics, perfumes, watches, and other high-end products.

The advantage of a luxury rigid box unprinted is that it can be easily customized with additional features, such as ribbon ties, foam inserts, or magnetic closures, to provide added protection and enhance the presentation of the product inside. This allows brands to create a unique and personalized packaging solution that aligns with their brand values and product offerings.

Styles 3

(Two Piece Luxury Rigid Box)

A two-piece luxury rigid box is a premium packaging solution that consists of two separate parts, a base and a lid, that fit together to create a complete box. This type of packaging is often made from high-quality materials, such as cardboard or chipboard, and is designed to provide a sophisticated and elegant look to the product it holds. The two-piece construction of this type of box allows for easy and secure assembly, making it an excellent choice for products that require extra protection during shipping or storage. The lid of the box is typically designed to fit snugly onto the base, providing a secure and tight closure that helps to keep the product inside safe and secure.

Two-piece luxury rigid boxes are commonly used for high-end products, such as jewellery, watches, perfumes, and cosmetics. They are available in a wide range of sizes, shapes, and colours, and can be customized with additional features, such as foam inserts, ribbon ties, or magnetic closures, to provide added protection and enhance the overall presentation of the product inside. Overall, a two-piece luxury rigid box is an excellent packaging solution for brands looking to create a premium and sophisticated presentation for their products.

Styles 4

(Luxury Shoe Rigid Box)

A luxury shoe rigid box is a premium packaging solution that is specifically designed to hold and protect shoes. This type of packaging is often made from high-quality materials, such as thick cardboard or chipboard, and is reinforced to provide extra strength and durability. The box is typically designed to fit the specific size and shape of the shoes it holds, providing a snug and secure fit that helps to protect the shoes from damage during shipping or storage. The exterior of the box can be customized with printed designs, branding, or other embellishments, providing a premium and sophisticated look that aligns with the brand and product.

Luxury shoe rigid boxes are commonly used by high-end shoe brands to create a premium presentation for their products. They are available in a wide range of sizes, colours, and styles, and can be customized with additional features, such as foam inserts or ribbon ties, to provide added protection and enhance the overall presentation of the shoes inside. Shoe rigid box is an excellent packaging solution for brands looking to create a premium and sophisticated look for their shoes and stand out in a crowded marketplace.

Custom Luxury Boxes

Get Luxury Rigid Boxes for your product packaging. We manufacture Customized Luxury Rigid Boxes using high-quality materials, a variety of box styles, and printing techniques to give your product a luxurious touch.

Although both products are used for packaging, there are still some differences between them which are described below:

- Custom Luxury Rigid Boxes and folding cartons are made of cardboard. However, the cardboard used in the manufacture of rigid boxes is four times thicker than cardboard.

- Folding cardboard boxes can be folded and can always be reassembled into a box, while custom rigid boxes are sturdy and therefore cannot be folded and reassembled as a box.

- Folding carton printing techniques are applied directly, while rigid boxes require other materials to be glued to the box for printing.

- Folding boxes are inexpensive and therefore can be produced in bulk quickly compared to Luxury Rigid Boxes.

- The dies used in folding cartons are expensive compared to those used in custom rigid cartons.

Creating Custom Luxury Boxes on Custom Packaging Boxes

The manufacturing process of custom rigid boxes on Custom Packaging Boxes is classified into five phases. The five steps include the material, the style of the box, the printing technique, the finishes, and finally some additional decoration to develop a brand image of your product as luxurious.

It all depends on the client’s needs and in case of any confusion our team of highly trained professionals is always available to assist you via WhatsApp. We provide design services to our clients for free.

- Innovative Styles and Design

- Custom Die Cut Packaging Boxes

- Enhance Product Presentation

- Accurate Sizes for All Products

- Well-Manufactured and Long Lasting Materials With High Quality,

- State-of-The-Art High-Quality Printing Services

- Best for Branding

- Delivery Within 5-7 Working Days After Finalization Of Your Design

You can reach us by calling or WhatsApp at +44 20 3290 1117 or emailing sale@custompackagingboxes.co.uk